US manufacturing activity contracted in June for a fourth month

Published in Business News

U.S. factory activity contracted in June for a fourth consecutive month as orders and employment shrank at a faster pace, extending the malaise in manufacturing.

The Institute for Supply Management’s manufacturing index edged up 0.5 point last month to 49, according to data released Tuesday. Readings below 50 indicate contraction. A measure of prices paid for raw materials showed slightly faster inflation.

Bookings contracted by the most in three months and have been shrinking for the past five months, likely a reflection of higher tariffs and a general slowdown in the economy. An index of order backlogs fell 2.8 points, the most in a year, to 44.3. Backlogs have contracted a record 33 straight months.

Government figures last week showed consumer spending declined in May by the most since the beginning of the year. The drop followed the weakest quarter for personal consumption since the onset of the pandemic.

Tepid demand and shrinking order backlogs help explain a faster rate of decline in factory employment. The ISM gauge dropped to a three-month low. It’s also contracted five straight months.

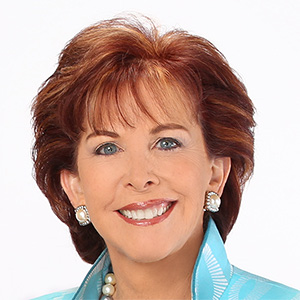

“The employment continuing to contract, you could look at it as companies continue to do the right thing to right size, their cost structure against a lack of new orders and backlogs,” Susan Spence, chair of the ISM Manufacturing Business Survey Committee, said on a call with reporters.

According to the report, for every comment on hiring, there were 3.2 indications of employment cutbacks. That is one of the widest ratios since the ISM began tracking employment comments and shows companies are focused on accelerating headcount reductions due to a lack of clarity on demand.

Nine manufacturing industries reported overall growth in June, led by apparel, petroleum and nonmetallic minerals products. Six contracted, led by textiles and wood products.

Select ISM industry comments

“Business has notably slowed in last four to six weeks. Customers do not want to make commitments in the wake of massive tariff uncertainty.” — Fabricated Metals

“The biopharmaceutical space is starting to see more pronounced headwinds: Stock prices have significantly eroded, companies are facing hiring freezes, and so on.” — Chemical Products

“The tariff mess has utterly stopped sales globally and domestically. Everyone is on pause. Orders have collapsed.” — Machinery

“Tariff volatility has impacted machinery, steel and specialized components. Also, potential shortages of skilled labor for construction, maintenance and installation.” — Food, Beverage & Tobacco Products

“Tariffs continue to cause confusion and uncertainty for long-term procurement decisions. The situation remains too volatile to firmly put such plans into place.” — Computer & Electronic Products

“Tariffs, chaos, sluggish economy, rising prices, Ukraine, Iran, geopolitical unrest around the world — all make for a landscape that is hellacious, and fatigue is setting in due to dealing with these issues across the spectrum.” — Primary Metals

“The word that best describes the current market outlook is ‘uncertainty.’ The erratic trade policy with on-again/off-again tariffs has led to price uncertainty for customers, who appear to be prepared to hold off large capital purchases until stability returns. This has resulted in further reductions in customer demand and softening sales for the balance of 2025.” — Transportation Equipment

Meanwhile, higher materials costs remain an issue for producers, the ISM survey indicated. The group’s price measure ticked up to 69.7, near the highest level since June 2022.

The import and export measures also contracted but at a slower pace. The import gauge jumped 7.5 points, the most in five years, after tumbling a month earlier.

Factory production shifted into expansion territory in June after shrinking for three months.

(With assistance from Mark Niquette.)

©2025 Bloomberg L.P. Visit bloomberg.com. Distributed by Tribune Content Agency, LLC.

Comments