Las Vegas is fueled by tourism -- but this firm bets big on manufacturing

Published in Business News

Las Vegas, the casino capital of America, isn’t known for having much manufacturing.

But in a sprawling industrial building just south of Harry Reid International Airport, a Canadian company is cranking out dressers, desks, headboards and more.

Foliot Furniture operates a manufacturing plant in Las Vegas that spans more than 300,000 square feet and makes furniture for hotels, student housing, shelters and other facilities.

Southern Nevada’s economy is fueled by tourism, and while the region has no shortage of industrial space, much of that is occupied by warehousing and distribution firms.

All told, manufacturing accounts for just 2.7 percent of the Las Vegas-area’s workforce — while the leisure and hospitality sector comprises 27 percent, according to federal data.

Foliot has a manufacturing and assembly plant in the Montreal area and a laminate-board production facility in the area, too.

It opened the Las Vegas plant, 7000 Placid St., in 2010. The company is celebrating 15 years in Southern Nevada with an event there on Sept. 26.

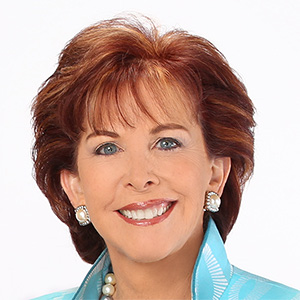

Foliot CEO Philip Giffard, a Canadian business executive who took the helm of the company last year, spoke with the Las Vegas Review-Journal this summer. The interview has been edited for length and clarity.

Q: Why did the company open a plant in Las Vegas, of all places?

A: The company was started 34 years ago by Daniel Foliot, with a manufacturing site north of Montreal. When we wanted to go after the U.S. market, we thought, let’s open on the West Coast. We already had East Coast capability that we could service out of Montreal. We looked at different cities in the U.S., and what made the most sense from a cost, transport, staffing perspective, that’s where Vegas came about.

Q: I have to imagine you get questions from people about the plant in Las Vegas. To an outsider, it might seem random and arbitrary. What do you tell people about why you’ve continued to have operations here, so far from your headquarters?

A: They’re sister sites; they have very similar capabilities, equipment and size. We needed the capacity. Our end customers are hotels, student residences, subsidized living, we’re going after cruise ships now; everything that has laminate furniture. The way we’re divided is we service all of our Eastern customers from Montreal and all of our Western customers, including in Canada, from our Vegas site.

Q: As you know, President Donald Trump has been threatening tariffs constantly to countries around the world, raising fears about higher costs. For you and your company, what has been the impact so far?

A: There are a few components that we buy that we cannot produce – door handles, hinges, things like that. We buy some of those in China. We’ve had some significant increases there. Today, we don’t face tariffs between Canada and the U.S., but we could reallocate operations so everything in the U.S. is manufactured in the U.S., everything in Canada is manufactured in Canada, so we would be safe from tariffs.

More importantly, just with the threats of tariffs is all the uncertainty in the marketplace. People travel less; the hotels are less busy, so they don’t renovate or build as many hotels. We do a lot of student residences; because of all the new legislation around international students, there aren’t as many students in the universities. We’ve reinvented ourselves in some new markets, but our traditional markets are suffering from all that uncertainty. We’re able to show a slight increase in sales year-over-year, but through a lot of hard work in going after new geographic markets, vertical markets.

Q: When Foliot opened in Las Vegas, it was during the Great Recession. The economy was a mess. Was that a factor in wanting to come here, because the company got a cheap deal on its building and could get lower-cost labor?

A: The overall cost, given the timing, was affordable. It played its part in the cost of rent but also access to labor. We’re heavily automated but it’s still labor-intensive. Depending on the season, close to 300 people work at our Vegas facility. We needed to have access to labor.

Q: Do you think Vegas has developed a substantial manufacturing industry, or is it still pretty small?

A: It’s still a small portion, but I think it’s made some headway versus 15 years ago. If you wanted to get a job in Vegas, you would have to work in hospitality. Today, there are big distribution centers, there are a few more manufacturing companies or sites than what there used to be, but there’s still some progress to be made, definitely. We’re working closely with UNLV in terms of students understanding that there is a possibility to stay local and not work in hospitality.

Q: How did COVID-19 impact Foliot’s business?

A: Greatly. Back then, our two main markets were hospitality and student residences. Those went down drastically, day one. That’s when we really started to diversify ourselves to think about who else was buying our type of furniture.

___

©2025 Las Vegas Review-Journal. Visit reviewjournal.com.. Distributed by Tribune Content Agency, LLC.

Comments