This company spent $35M designing next-gen hospital bed

Published in Business News

EDEN PRAIRIE, Minnesota — Agiliti has invested more than $35 million to develop a next-generation hospital bed, one that fits the needs of all kinds of patients and the health care workers taking care of them.

The company that rents and services hospital equipment has moved into manufacturing its own bed after years of handling models from other manufacturers.

“When you eat your own cooking, you tend to be a better chef,” said Tom Leonard, Agiliti’s chief executive, during a visit to the company’s Eagan service center.

After four years of development, $30 million in research costs and $5 million more in manufacturing upgrades, Agiliti is ready to introduce its Essentia bed.

The Essentia name is a nod to essential workers (not the Duluth health system) and was designed to make a health care worker’s life easier and less physically taxing while being more comfortable and therapeutic for patients.

Post-COVID hospital staffing levels remain thin, and Agiliti sees a market for hospital equipment that can benefit patients while reducing physical stress on staff.

So Agiliti built its bed frame to address the needs they consistently heard from customers and patients on adjustable bed height, side rails and mattress retainers.

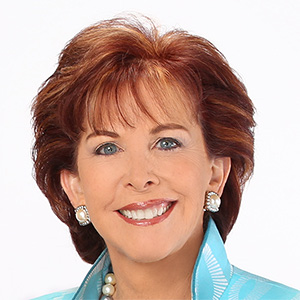

“We brought that feedback together into one bed so customers don’t have to rent different beds that operate differently for different reasons,” said Kristen Thurman, vice president of product management and clinical affairs at Agiliti.

The Essentia bed and related accessories should be a major financial driver for the $1.2 billion company for years to come.

“Our success here is not just critical to the financial future of the business,” Leonard said. “I don’t expect that this is the last product that we will manufacture.”

Razor blade business model

The Essentia bed was the direct result of manufacturing capability Agiliti got from its $230 million acquisition of Sizewise in 2021. Sizewise is a maker of hospital beds specializing in oversize frames and surfaces for the bariatric market.

Leonard thinks of a hospital bed using the razor and razor-blade business model. The bed frame is the durable product and the surfaces (mattresses) are the replaceable items that pair with a frame.

Depending on use, a hospital bed frame can last 10 years, while surfaces can last three to seven years.

According to Leonard, the health care industry buys about 50,000 to 70,000 new hospital beds annually. Last year that was about a $2.5 billion market in the United States.

Agiliti didn’t disclose the purchase price of the Essentia bed, which is just now reaching the market after 1,000 patient days of final evaluation. Hospital beds from makers like Hillrom, SonderCare, Stryker and others can range from $2,000 to well over $10,000.

The Essentia bed frames are being built in Kansas, and the surfaces are being built in California. The company also has some manufacturing capability in Mexico.

According to Leonard, Agiliti made the decision to manufacture in the U.S. years ago, which has provided the company some advantages.

“We have very little impact today from the vacillations on tariffs,” Leonard said. “There’s some things we have to source (internationally), but very little.”

A decade of growth

Leonard joined Agiliti in 2015 when the company was called Universal Hospital Services. At the time it had about $400 million in annual revenue, mainly from rental income, but was financially troubled.

Under Leonard, the company added more maintenance and management services, expanded geographically and increased employment from 2,300 to nearly 6,000.

“We’ve done that not by trying to cut our way to success, but rather by investing in our growth,” Leonard said.

The firm changed its name to Agiliti in 2018.

Agiliti had 2024 revenue of $1.2 billion; according to Leonard, about 30% of the revenue was associated with managing hospital beds, which includes the frames and mattresses.

The company’s growth also came while transitioning though private equity owners and a brief run as a publicly traded company. The company is currently owned by an affiliate of the private equity company Thomas H. Lee Partners.

Agiliti owns or manages more than a million pieces of health care equipment, including beds, surgical equipment and stockpiles of emergency equipment for state and federal governments.

Today more than 90% of hospitals in the United States are within 100 miles of one of Agiliti’s more than 130 U.S. service centers that clean, maintain, inspect, repair and deploy hospital equipment through a fleet of more than 1,700 vehicles.

The service center in Eagan opened in April 2024. At 32,000 square feet, it’s among the larger Agiliti sites. Open 24/7, it employs about 35 people, maintains approximately 2,000 to 2,500 pieces of medical equipment in the facility and is responsible for about 5,000 additional pieces deployed in approximately 150 nearby hospitals, surgery centers or other health care facilities.

Built from experience

Agiliti has been one of the biggest purchasers of hospital beds from other manufacturers. As it serviced those beds over the years, the company got plenty of feedback on what worked and what didn’t.

The Essentia bed has a number of features to benefit both patients and caregivers. It’s an integrated system with a frame that can accommodate different surfaces/mattresses meant for different types of patients.

Those mattresses and surfaces can help prevent pressure wounds (bedsores) and help regulate body temperature to make sleep more comfortable.

The frame itself can be lowered to a height of 11½ inches, which allows patients to sit on the edge of the bed and place their feet securely on the floor. The length and width of the frame are also adjustable.

Bed rails are easily positioned to help patients steady themselves, but the rails can also easily move out of the way so staff can attend to patients without reaching.

The main functions of the bed can be accessed at the foot of the bed and from either side. Menu functions are intuitive, the company says, and the various alarms and alerts associated with the bed are customizable.

One of the bed’s most unusual features addresses today’s care procedures, which aim to get nearly all patients moving or at least in weight-bearing positions as soon as practical.

The Essentia bed can tilt up to 20 degrees, higher than competitors. That tilt puts even the most immobile patients in weight-bearing positions that aid in recovery, and also helps prevent pressure sores.

“The more they can mobilize, the less pressure injuries they’re going to get,” said VP Thurman.

©2025 The Minnesota Star Tribune. Visit at startribune.com. Distributed by Tribune Content Agency, LLC.

Comments